Nano-silica is an amorphous white powder, a non-toxic, odorless, and pollution-free non-metallic material. It possesses unique properties, such as optical properties that resist ultraviolet radiation; it can also improve the anti-aging and chemical corrosion resistance of materials; dispersing nano-silica in materials can improve their strength and elasticity; and it also has the function of adsorbing pigment ions and reducing pigment fading.

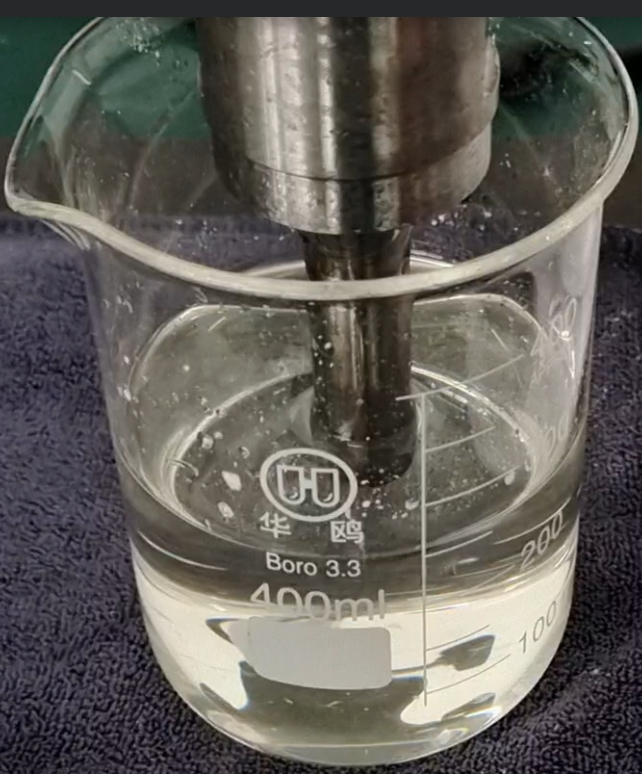

The precipitation process of nano-silica utilizes ultrasonic dispersion technology. When the liquid is subjected to ultrasound, a large number of microbubbles are generated in the liquid medium. During the formation and collapse of microbubbles, energy is released, producing a cavitation effect. The instantaneous generation of cavitation creates strong vibrational waves. The rapid formation and sudden collapse of cavitation bubbles in the liquid create a brief high-energy environment, generating high-speed microjets. This significantly weakens the nano-interaction energy between nanoparticles, effectively preventing nanoparticle aggregation and ensuring their full dispersion into tiny particles. The cavitation effect of ultrasound generates powerful shock waves and microjets, which produce a strong impact at the liquid-solid interface, effectively preventing the growth of crystal nuclei and destroying and weakening the surface interaction forces of the generated particles and the intermolecular forces between water molecules, thereby further preventing particle aggregation.

Post time: Jan-09-2026