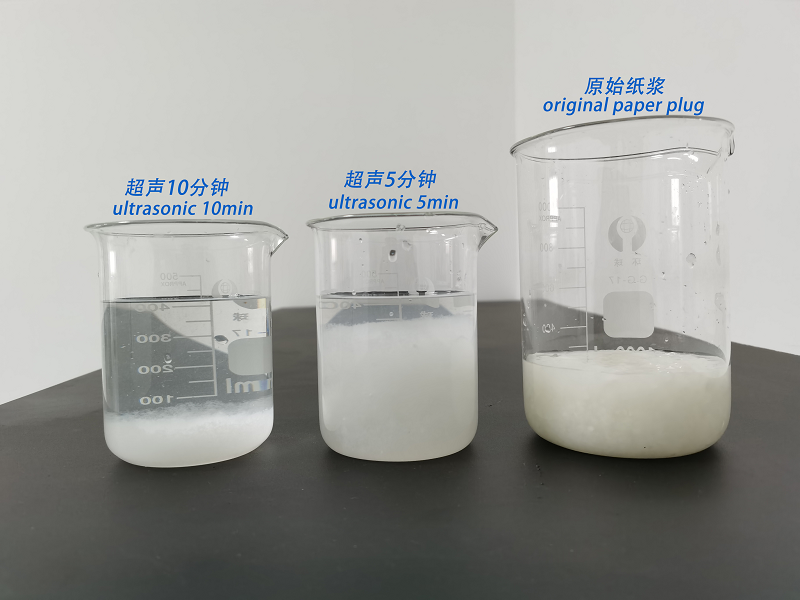

Ultrasonic homogenization technology promotes fiberization. Ultrasonic treatment not only has a mechanical beating effect on fibers, but also increases their water retention, accessibility, and reactivity. For fibers containing a high amount of pectin, ultrasonic homogenizer can achieve excellent degumming results. Ultrasonic dispersion technology is particularly effective for surface modification of synthetic fibers. It activates the fiber surface, increasing the number of oxygen-containing functional groups and leading to an increase in polar molecules in the fiber’s surface tension. Simultaneously, ultrasound has an etching effect on the fiber surface, increasing the specific surface area and significantly enhancing the interlayer bonding ability. Cellulose fibers depolymerize after ultrasonic homogenization. The frictional force generated by the difference in ultrasonic velocity between the polymer and the liquid disrupts the fiber structure. Using ultrasound to treat various pulps causes fiber swelling, outer layer peeling, and fine fibrillation, thereby increasing paper strength.

Post time: Jan-22-2026