2020 Good Quality Ultrasonic Cbd Oil Processing Equipment - ultrasonic biodiesel reactor continuous liquid chemic mixer for nanoemulsion emulsifier – JH

2020 Good Quality Ultrasonic Cbd Oil Processing Equipment - ultrasonic biodiesel reactor continuous liquid chemic mixer for nanoemulsion emulsifier – JH Detail:

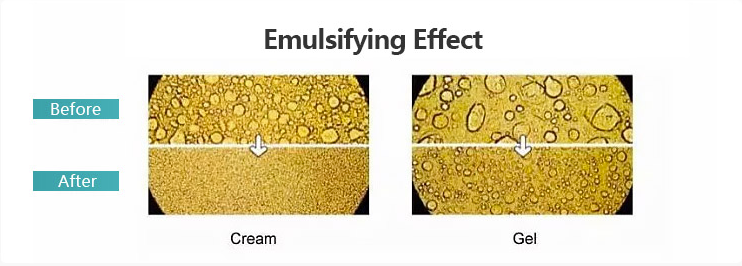

When you make biodiesel, slow reaction kinetics and poor mass transfer are lowering your biodiesel plant capacity and your biodiesel yield and quality. JH ultrasonic reactors improve the transesterification kinetics significantly. Therefore lower excess methanol and less catalyst are required for biodiesel processing. Biodiesel is commonly produced in batch reactors using heat and mechanical mixing as energy input. Ultrasonic cavitational mixing is an effective alternative means to achieve a better mixing in commercial biodiesel processing. Ultrasonic cavitation provides the necessary activation energy for the industrial biodiesel transesterification. Ultrasonic processing of biodiesel involves the following steps:

1.The vegetable oil or animal fat is being mixed with the methanol (which makes methyl esters) or ethanol (for ethyl esters) and sodium or potassium methoxide or hydroxide.

2.The mix is heated, e.g. to temperatures between 45 and 65degC.

3.The heated mix is being sonicated inline for 5 to 30 seconds.

4.Glycerin drops out or is separated using centrifuges.

5.The converted biodiesel is washed with water. Most commonly, the sonication is performed at an elevated pressure (1 to 3bar, gauge pressure) using a feed pump and an adjustable back-pressure valve next to the flow cell.

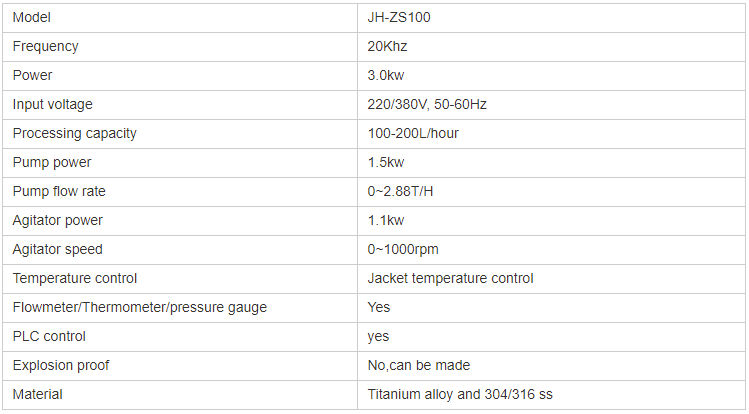

SPECIFICATIONS:

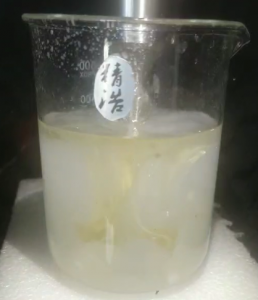

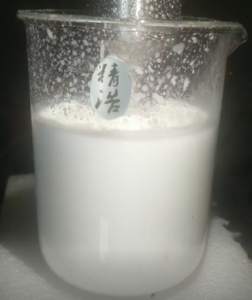

Product detail pictures:

Related Product Guide:

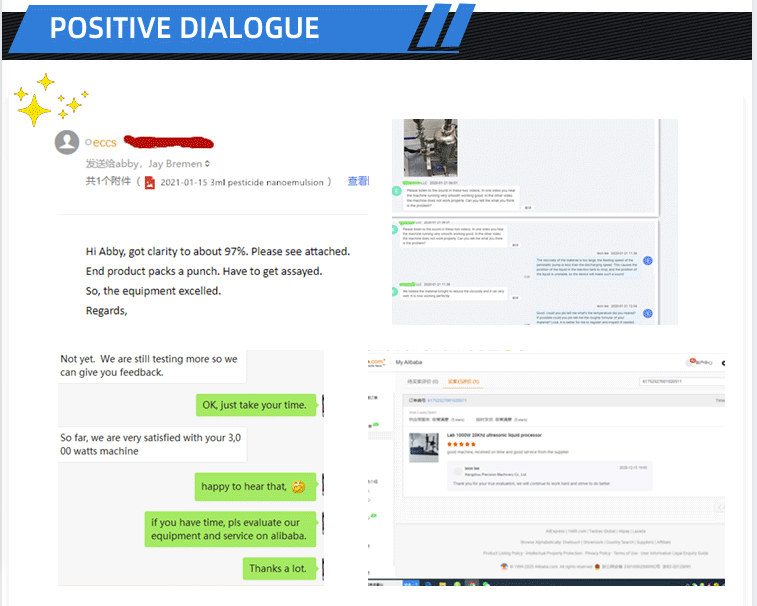

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for 2020 Good Quality Ultrasonic Cbd Oil Processing Equipment - ultrasonic biodiesel reactor continuous liquid chemic mixer for nanoemulsion emulsifier – JH , The product will supply to all over the world, such as: Rio de Janeiro, Qatar, Portugal, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

xy.jpg)