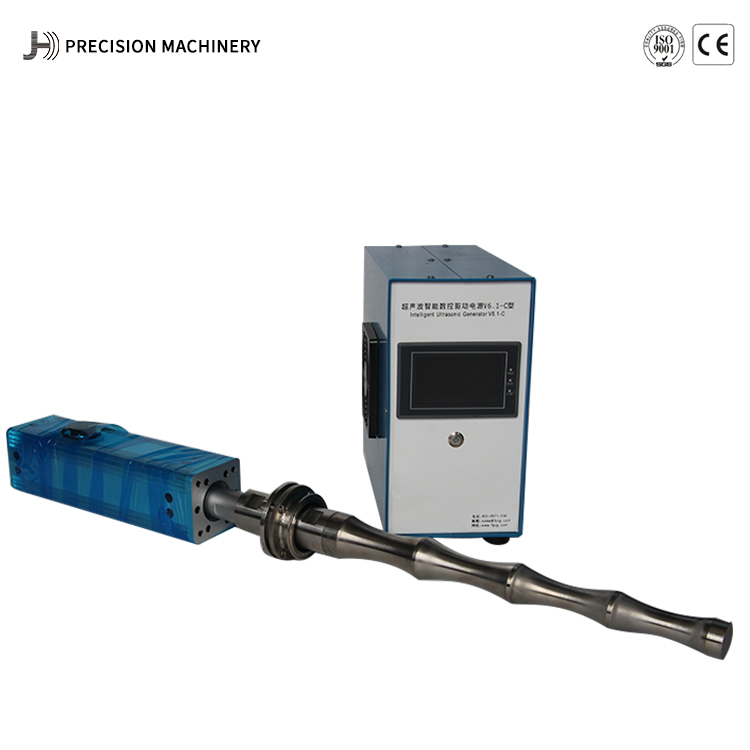

2020 Good Quality Ultrasonic Dispersion Machine - 20Khz ultrasonic carbon nanotube dispersion machine – JH

2020 Good Quality Ultrasonic Dispersion Machine - 20Khz ultrasonic carbon nanotube dispersion machine – JH Detail:

Carbonnanotubes are strong and flexible but very cohesive. They are difficult to disperse into liquids, such as water, ethanol, oil, polymer or epoxy resin. Ultrasound is an effective method to obtain discrete – single-dispersed – carbonnanotubes.

Carbonnanotubes (CNT) are used in adhesives, coatings and polymers and as electrically conductive fillers in plastics to dissipate static charges in electrical equipment and in electrostatically paintable automobile body panels. By the use of nanotubes, polymers can be made more resistant against temperatures, harsh chemicals, corrosive environments, extreme pressures and abrasion.

SPECIFICATIONS:

| MODEL | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | NO | |||

ADVANTAGES:

1.Compared with the dispersion in the traditional harsh environment, ultrasonic dispersion can reduce the damage to the structure of single-walled carbon nanotubes and maintain a long single-walled carbon nanotube.

2.It can be completely and evenly dispersed to better achieve the performance of carbon nanotubes.

3.It can quickly disperse carbon nanotubes, avoid degradation of carbon nanotubes, and obtain high concentration carbon nanotube solutions.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of 2020 Good Quality Ultrasonic Dispersion Machine - 20Khz ultrasonic carbon nanotube dispersion machine – JH , The product will supply to all over the world, such as: Bangladesh, Hungary, Australia, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.