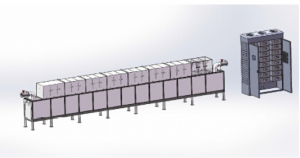

Best quality 1500w Ultrasonic Dispersion Equipment - Ultrasonic Graphene Dispersing Equipment – JH

Best quality 1500w Ultrasonic Dispersion Equipment - Ultrasonic Graphene Dispersing Equipment – JH Detail:

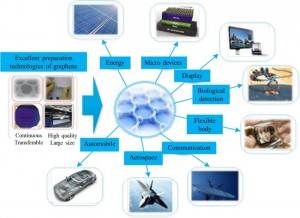

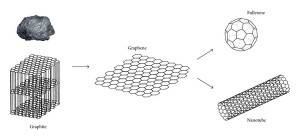

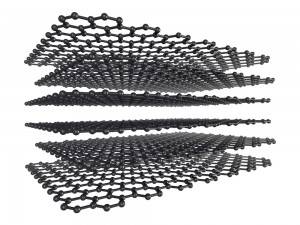

Due to the extraordinary material properties of graphene, such as: strength, hardness, service life, etc. In recent years, graphene has become more and more widely used. In order to incorporate graphene into the composite material and play its role, it must be dispersed into individual nanosheets. The higher the degree of deagglomeration, the more obvious the role of graphene.

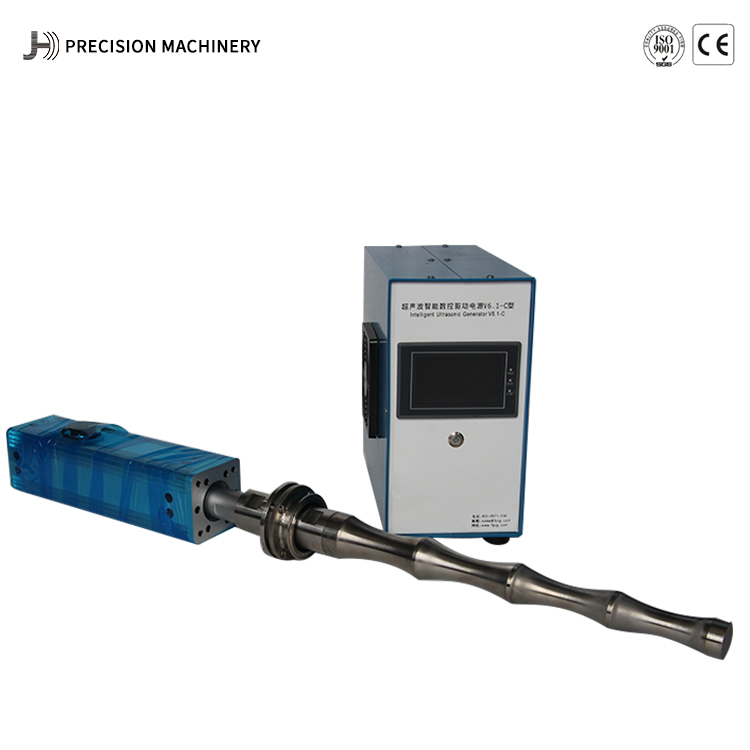

Ultrasonic vibration overcomes the van der Waals force with a high shear force of 20,000 times per second, thereby preparing graphene with high conductivity, good dispersion and high concentration. Since the ultrasonic treatment process can be precisely controlled, the chemical and crystal structure of the graphene obtained by ultrasonic dispersion will not be destroyed.

SPECIFICATIONS:

|

Model |

JH-JX10 |

JH-JX25 |

JH-JX50 |

JH-JX100 |

JH-JX200 |

JH-JX300 |

|

Yearly output |

10T |

25T |

50T |

100T |

200T |

300T |

|

Install area |

5㎡ |

10㎡ |

20㎡ |

40㎡ |

60㎡ |

80㎡ |

|

Total power |

18000W |

36000W |

72000W |

14000W |

288000W |

432000W |

|

QTY of ultrasonic equipment |

6 |

12 |

24 |

48 |

96 |

144 |

|

Input voltage |

220V /380V,50Hz |

|||||

|

Frequency |

20KHz±1KHz |

|||||

ADVANTAGES:

1.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

2.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

3.Can be dispersed into high viscosity and high concentration solutions.

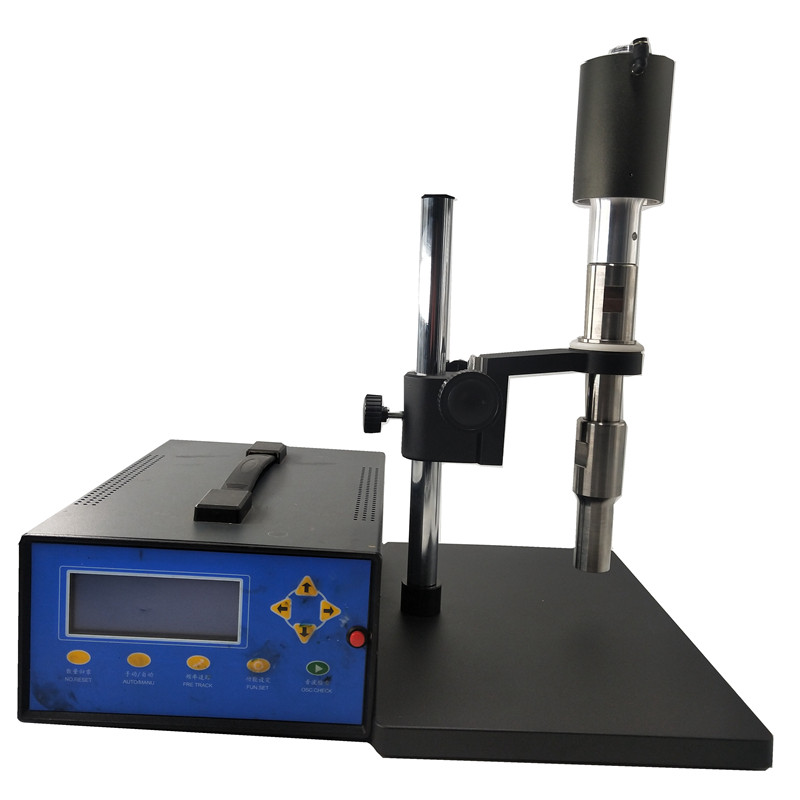

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for Best quality 1500w Ultrasonic Dispersion Equipment - Ultrasonic Graphene Dispersing Equipment – JH , The product will supply to all over the world, such as: Jakarta, Greek, Chile, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!