Factory Supply 20k 3000w Ultrasonic Homogenizer For Dispersion Graphene - 20Khz ultrasonic pigment coating paint dispersing machine – JH

Factory Supply 20k 3000w Ultrasonic Homogenizer For Dispersion Graphene - 20Khz ultrasonic pigment coating paint dispersing machine – JH Detail:

Ultrasonic dispersing is a mechanical process to reduce small particles in a liquid so that they become uniformly small and evenly distributed.

When ultrasonic dispersing machines are used as homogenizers, the objective is to reduce small particles in a liquid to improve uniformity and stability. These particles (disperse phase) can be either solids or liquids. A reduction in the mean diameter of the particles increases the number of individual particles. This leads to a reduction of the average particle distance and increases the particle surface area.

Ultrasonic cavitation produces countless high and low pressure zones in the liquid. These high and low pressure zones continuously impact solid particles such as: TiO2, SiO2, ZrO2, ZnO, CeO2 during the circulation process to deagglomerate them, reduce the size of the particles, and increase the surface contact area between the particles, so disperse evenly into the solution.

SPECIFICATIONS:

| MODEL | JH-BL20 |

| Frequency | 20Khz |

| Power | 3000W |

| Input voltage | 110/220/380V, 50/60Hz |

| Agitator speed | 0~600rpm |

| Temperature display | Yes |

| Peristaltic pump speed | 60~600rpm |

| Flow rate | 415~12000ml/min |

| Pressure | 0.3Mpa |

| OLED display | Yes |

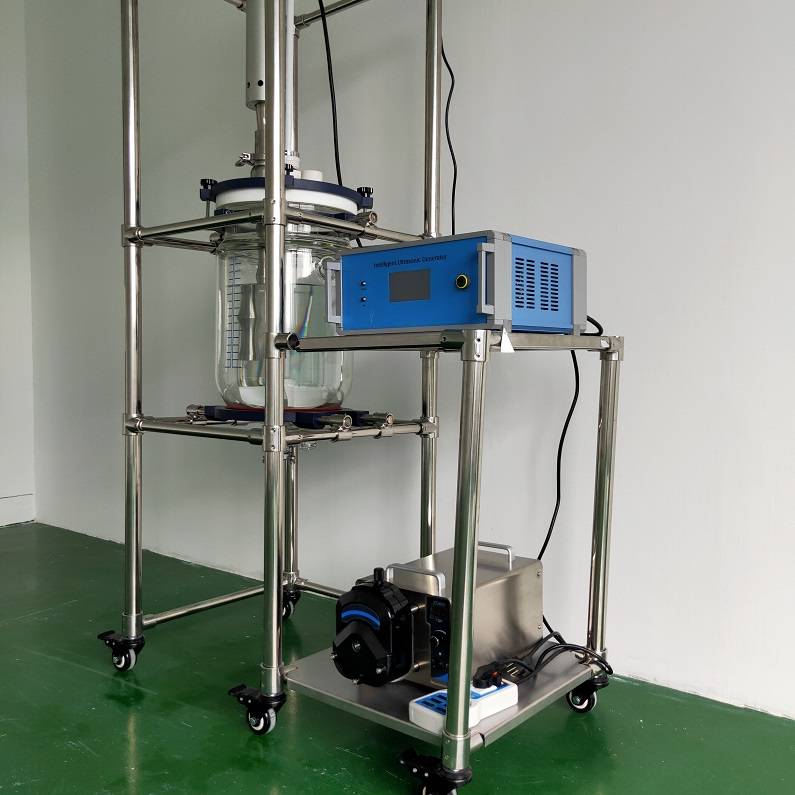

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, shopper first" for Factory Supply 20k 3000w Ultrasonic Homogenizer For Dispersion Graphene - 20Khz ultrasonic pigment coating paint dispersing machine – JH , The product will supply to all over the world, such as: Cairo, Guatemala, Guyana, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.