Factory wholesale Ultrasonic Liquid Processing Equipment - 20Khz ultrasonic dispersing homoegnizer machine – JH

Factory wholesale Ultrasonic Liquid Processing Equipment - 20Khz ultrasonic dispersing homoegnizer machine – JH Detail:

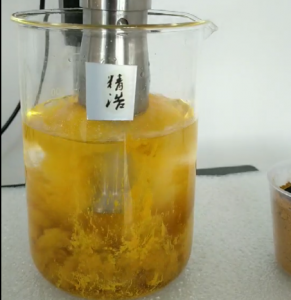

Ultrasonic homogenizing is a mechanical process to reduce small particles in a liquid so that they become uniformly small and evenly distributed.

When ultrasonic processors are used as homogenizers, the objective is to reduce small particles in a liquid to improve uniformity and stability. These particles (disperse phase) can be either solids or liquids. A reduction in the mean diameter of the particles increases the number of individual particles. This leads to a reduction of the average particle distance and increases the particle surface area.

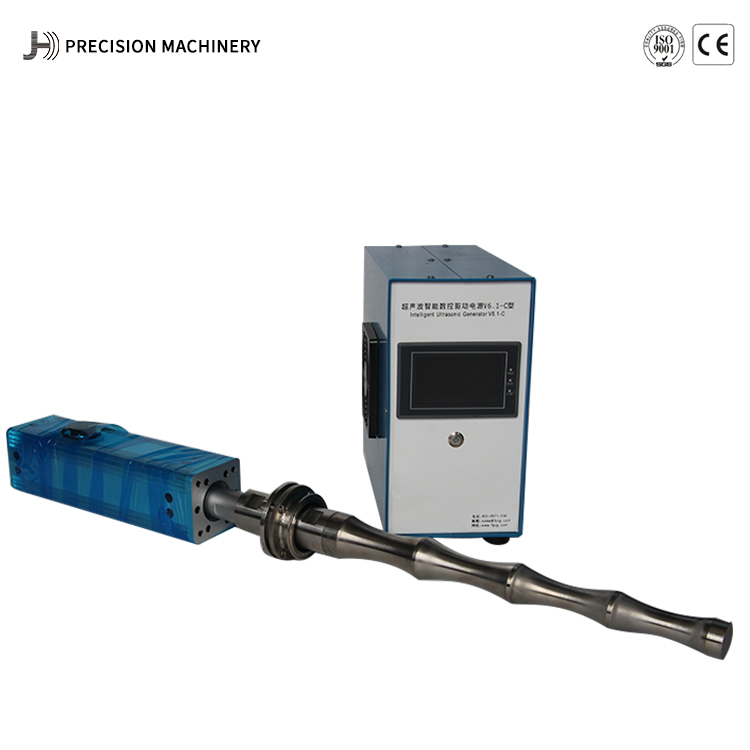

JH-ZS50 series can be used for large-scale experiments and small and medium-sized industrial production.

SPECIFICATIONS:

| MODEL | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | NO | |||

ADVANTAGES:

1) Intelligent control technology, stable ultrasonic energy output,stable work for 24 hours per day.

2) Automatic frequency tracking mode, ultrasonic transducer working frequency real-time tracking.

3) Multiple protection mechanisms to extend service life to more than 5 years.

4) Energy focus design, high output density, improve efficiency to 200 times in the suitable area.

5) Support static or cyclic working mode .

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Factory wholesale Ultrasonic Liquid Processing Equipment - 20Khz ultrasonic dispersing homoegnizer machine – JH , The product will supply to all over the world, such as: French, South Africa, New York, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.