Factory wholesale Ultrasonic Processors For Biodiesel Production - 20Khz ultrasonic dispersing homoegnizer machine – JH

Factory wholesale Ultrasonic Processors For Biodiesel Production - 20Khz ultrasonic dispersing homoegnizer machine – JH Detail:

Ultrasonic homogenizing is a mechanical process to reduce small particles in a liquid so that they become uniformly small and evenly distributed.

When ultrasonic processors are used as homogenizers, the objective is to reduce small particles in a liquid to improve uniformity and stability. These particles (disperse phase) can be either solids or liquids. A reduction in the mean diameter of the particles increases the number of individual particles. This leads to a reduction of the average particle distance and increases the particle surface area.

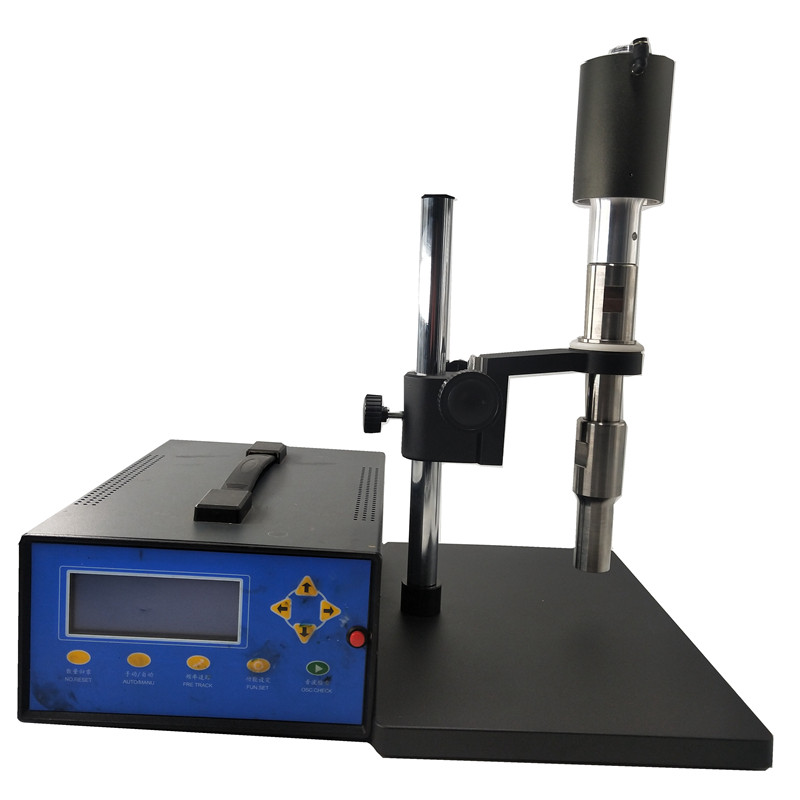

JH-ZS50 series can be used for large-scale experiments and small and medium-sized industrial production.

SPECIFICATIONS:

| MODEL | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | NO | |||

ADVANTAGES:

1) Intelligent control technology, stable ultrasonic energy output,stable work for 24 hours per day.

2) Automatic frequency tracking mode, ultrasonic transducer working frequency real-time tracking.

3) Multiple protection mechanisms to extend service life to more than 5 years.

4) Energy focus design, high output density, improve efficiency to 200 times in the suitable area.

5) Support static or cyclic working mode .

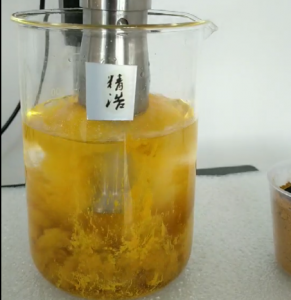

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth", will continue to serve outdated and new consumers from home and overseas whole-heatedly for Factory wholesale Ultrasonic Processors For Biodiesel Production - 20Khz ultrasonic dispersing homoegnizer machine – JH , The product will supply to all over the world, such as: Botswana, Canada, Surabaya, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a professional engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We are your best choice.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.