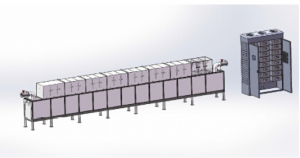

Good quality Ultrasonic Dispersion Mixer - Ultrasonic Graphene Dispersing Equipment – JH

Good quality Ultrasonic Dispersion Mixer - Ultrasonic Graphene Dispersing Equipment – JH Detail:

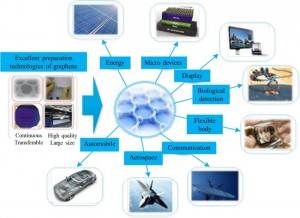

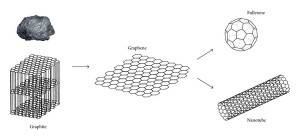

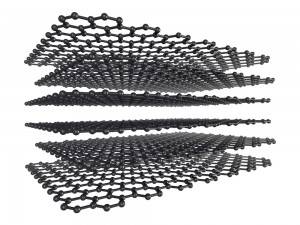

Due to the extraordinary material properties of graphene, such as: strength, hardness, service life, etc. In recent years, graphene has become more and more widely used. In order to incorporate graphene into the composite material and play its role, it must be dispersed into individual nanosheets. The higher the degree of deagglomeration, the more obvious the role of graphene.

Ultrasonic vibration overcomes the van der Waals force with a high shear force of 20,000 times per second, thereby preparing graphene with high conductivity, good dispersion and high concentration. Since the ultrasonic treatment process can be precisely controlled, the chemical and crystal structure of the graphene obtained by ultrasonic dispersion will not be destroyed.

SPECIFICATIONS:

|

Model |

JH-JX10 |

JH-JX25 |

JH-JX50 |

JH-JX100 |

JH-JX200 |

JH-JX300 |

|

Yearly output |

10T |

25T |

50T |

100T |

200T |

300T |

|

Install area |

5㎡ |

10㎡ |

20㎡ |

40㎡ |

60㎡ |

80㎡ |

|

Total power |

18000W |

36000W |

72000W |

14000W |

288000W |

432000W |

|

QTY of ultrasonic equipment |

6 |

12 |

24 |

48 |

96 |

144 |

|

Input voltage |

220V /380V,50Hz |

|||||

|

Frequency |

20KHz±1KHz |

|||||

ADVANTAGES:

1.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

2.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

3.Can be dispersed into high viscosity and high concentration solutions.

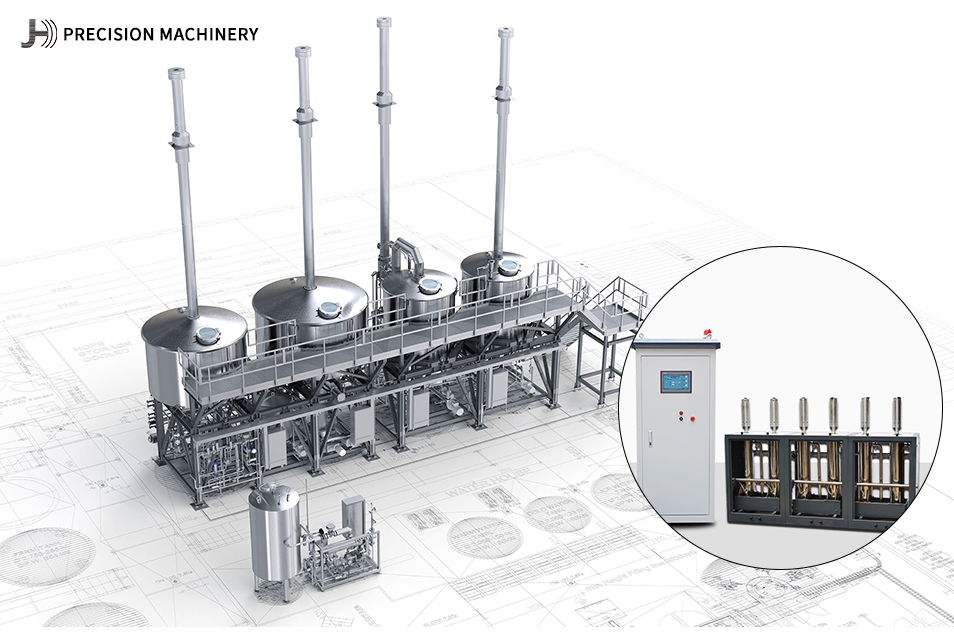

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for Good quality Ultrasonic Dispersion Mixer - Ultrasonic Graphene Dispersing Equipment – JH , The product will supply to all over the world, such as: Pakistan, Kenya, French, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.