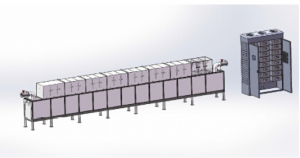

High Quality for Homogenizing And Dispersing Machine - Ultrasonic Graphene Dispersing Equipment – JH

High Quality for Homogenizing And Dispersing Machine - Ultrasonic Graphene Dispersing Equipment – JH Detail:

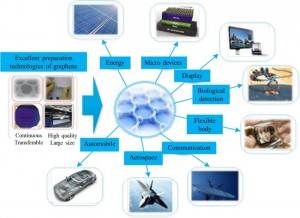

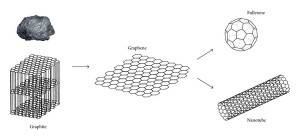

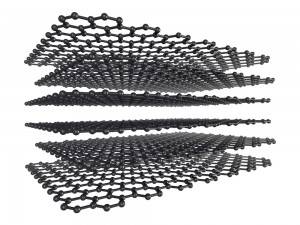

Due to the extraordinary material properties of graphene, such as: strength, hardness, service life, etc. In recent years, graphene has become more and more widely used. In order to incorporate graphene into the composite material and play its role, it must be dispersed into individual nanosheets. The higher the degree of deagglomeration, the more obvious the role of graphene.

Ultrasonic vibration overcomes the van der Waals force with a high shear force of 20,000 times per second, thereby preparing graphene with high conductivity, good dispersion and high concentration. Since the ultrasonic treatment process can be precisely controlled, the chemical and crystal structure of the graphene obtained by ultrasonic dispersion will not be destroyed.

SPECIFICATIONS:

|

Model |

JH-JX10 |

JH-JX25 |

JH-JX50 |

JH-JX100 |

JH-JX200 |

JH-JX300 |

|

Yearly output |

10T |

25T |

50T |

100T |

200T |

300T |

|

Install area |

5㎡ |

10㎡ |

20㎡ |

40㎡ |

60㎡ |

80㎡ |

|

Total power |

18000W |

36000W |

72000W |

14000W |

288000W |

432000W |

|

QTY of ultrasonic equipment |

6 |

12 |

24 |

48 |

96 |

144 |

|

Input voltage |

220V /380V,50Hz |

|||||

|

Frequency |

20KHz±1KHz |

|||||

ADVANTAGES:

1.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

2.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

3.Can be dispersed into high viscosity and high concentration solutions.

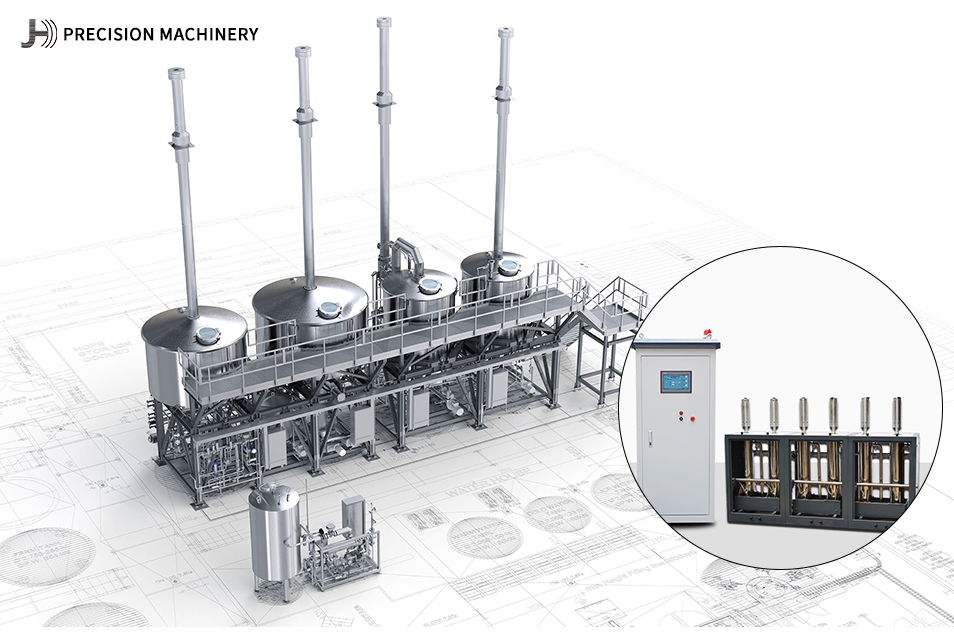

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of High Quality for Homogenizing And Dispersing Machine - Ultrasonic Graphene Dispersing Equipment – JH , The product will supply to all over the world, such as: Qatar, moldova, Czech, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.