Manufacturer of Ultrasonic Sonochemistry Machine For Biodiesel - ultrasonic carbon nanotubes dispersion machine – JH

Manufacturer of Ultrasonic Sonochemistry Machine For Biodiesel - ultrasonic carbon nanotubes dispersion machine – JH Detail:

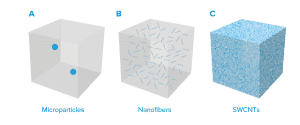

Carbon nanotubes have many uses, and can be used in adhesives, coatings, polymers and as conductive fillers in plastics. By using carbon nanotubes, the polymer’s high temperature resistance, corrosion resistance, pressure resistance and wear resistance have been significantly improved.

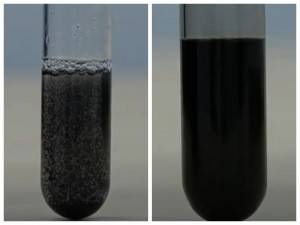

Ultrasonic waves generate powerful shearing forces through 20,000 vibrations per second. The bonding force between carbon nanotubes can be overcome, and the tubes are separated evenly. Generally, the crude nanotube dispersion is pre-mixed by mechanical stirring, and then further dispersed into small beams or single carbon nanotubes using ultrasonic waves. It is recommended to use pipeline ultrasonic equipment.

SPECIFICATIONS:

| Model | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | NO | |||

ADVANTAGES:

1.Compared with the dispersion in the traditional harsh environment, ultrasonic dispersion can reduce the damage to the structure of single-walled carbon nanotubes and maintain a long single-walled carbon nanotube.

2.It can be completely and evenly dispersed to better achieve the performance of carbon nanotubes.

3.It can quickly disperse carbon nanotubes, avoid degradation of carbon nanotubes, and obtain high concentration carbon nanotube solutions.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Manufacturer of Ultrasonic Sonochemistry Machine For Biodiesel - ultrasonic carbon nanotubes dispersion machine – JH , The product will supply to all over the world, such as: Denver, Barbados, Cape Town, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we have been going to have a bright prospect and to be distributed all over the world in the years to come.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.