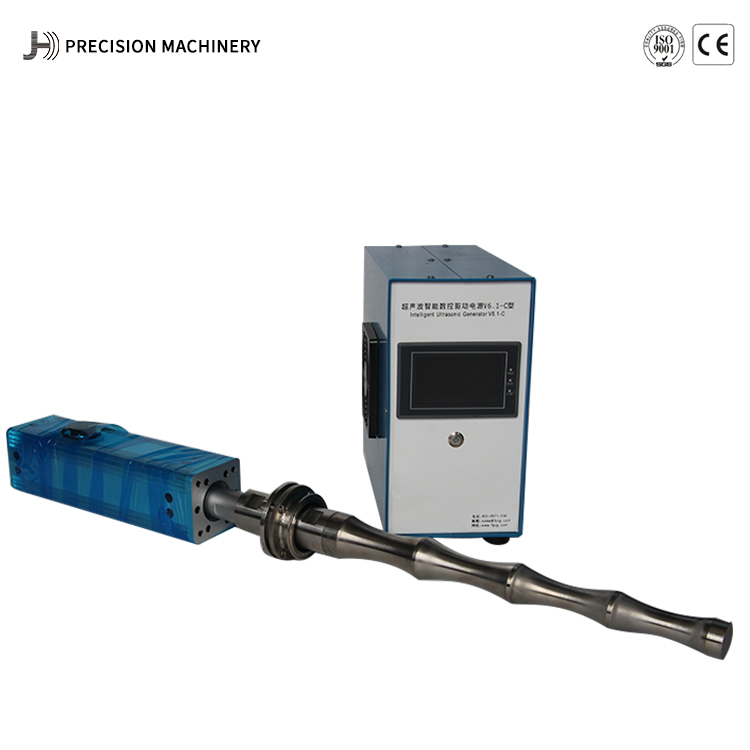

Wholesale Price 2000w Ultrasonic Processor - Ultrasonic dispersion sonicator homogenizer – JH

Wholesale Price 2000w Ultrasonic Processor - Ultrasonic dispersion sonicator homogenizer – JH Detail:

Ultrasonic homogenizing is a mechanical process to reduce small particles in a liquid so that they become uniformly small and evenly distributed. Sonicators work by generating intense sonic pressure waves in a liquid media. The pressure waves cause streaming in the liquid and, under the right conditions, rapid formation of micro-bubbles which grow and coalesce until they reach their resonant size, vibrate violently, and eventually collapse. This phenomenon is called cavitation. The implosion of the vapor phase bubbles generates a shock wave with sufficient energy to break covalent bonds. Shear from the imploding cavitation bubbles as well as from eddying induced by the vibrating sonic transducer disrupt cells.

SPECIFICATIONS:

| MODEL | JH1500W-20 | JH2000W-20 | JH3000W-20 |

| Frequency | 20Khz | 20Khz | 20Khz |

| Power | 1.5Kw | 2.0Kw | 3.0Kw |

| Input voltage | 110/220V, 50/60Hz | ||

| Amplitude | 30~60μm | 35~70μm | 30~100μm |

| Amplitude adjustable | 50~100% | 30~100% | |

| Connection | Snap flange or customized | ||

| Cooling | Cooling fan | ||

| Operation Method | Button operation | Touch screen operation | |

| Horn material | Titanium alloy | ||

| Temperature | ≤100℃ | ||

| Pressure | ≤0.6MPa | ||

ADVANTAGES:

1.The device can work continuously for 24 hours, and the life of the transducer is up to 50000 hours.

2.The horn can be customized according to different industries and different working environments in order to achieve the best processing effect.

3.Can be connected to PLC, making operation and information recording more convenient.

4.Automatically adjust the output energy according to the change of liquid to ensure that the dispersion effect is always in the best state.

5.Can handle temperature sensitive liquids.

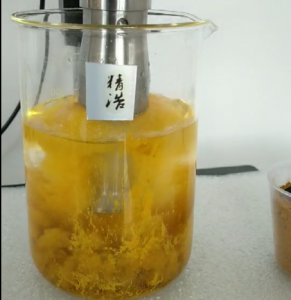

Product detail pictures:

Related Product Guide:

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for Wholesale Price 2000w Ultrasonic Processor - Ultrasonic dispersion sonicator homogenizer – JH , The product will supply to all over the world, such as: Romania, Australia, Palestine, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.