-

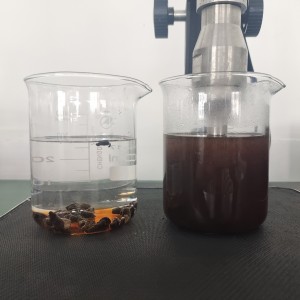

ultrasonic pea collagen protein extraction equipment

DESCRIPTIONS: As a green extraction technology, ultrasonic extraction is being more and more applied to the fields of food, medicine, daily chemical products and so on. In the complete traditional extraction system, ultrasonic extraction is generally used in the preprocessing link. Taking protein extraction as an example, due to the powerful cavitation effect of ultrasound, the physical properties of protein have changed significantly, including size reduction, rheology, conductivity and ζ Po... -

xy-300x300.jpg)

large capacity ultrasonic herb extract machine for essential oil extracting

Ultrasonic extraction: Ultrasonic extraction is a technology that uses the cavitation effect, mechanical effect and thermal effect of ultrasonic wave to extract the effective components of substances (herbs) by increasing the moving speed of medium molecules and increasing the penetration of medium. Ultrasonic cavitation Ultrasonic waves vibrate 20000 times per second to increase the dissolved microbubbles in the medium, form a resonant cavity, and then close instantaneously to form a power... -

500w lab ultrasonic herb plant extraction machine for extracting

DESCRIPTIONS: Ultrasonic extraction refers to the use of ultrasonic extractors to increase the motion frequency and speed of material molecules and increase the solvent penetration by using the multi-level effects such as strong cavitation stress effect, mechanical vibration, disturbance effect, high acceleration, emulsification, diffusion, crushing and stirring caused by ultrasonic radiation pressure, so as to accelerate the target components into the solvent, Mature extraction technology to... -

ultrasonic cbd oil liposomes nanoemulsion mixer homogenizer

DESCRIPTIONS: Ultrasonic homogenizer uses ultrasonic cavitation and other physical effects in liquid to achieve homogenization effect. Physical action refers to that ultrasonic wave can form effective agitation and flow in liquid, destroy the structure of medium and crush particles in liquid. It is mainly the change of particle surface morphology caused by liquid collision, microphase flow and shock wave. Cavitation refers to that under the action of ultrasound, the liquid produces holes in p... -

3000w continuous ultrasonic nanoemulsion homogenizer

DESCRIPTIONS: Ultrasonic emulsification refers to the process of mixing two (or more) immiscible liquids to form a dispersion system under the action of ultrasonic energy, in which one liquid is evenly distributed in the other liquid to form an emulsion. Ultrasonic homogenizer can better mix liquid-liquid and solid-liquid solutions. Ultrasonic vibration will produce millions of tiny bubbles, which immediately form and collapse to form a powerful shock wave, which will rupture cells or partic... -

lab portable ultrasonic cell crusher

The ultrasonic cell crusher uses the dispersion effect of ultrasonic wave in the liquid to make the liquid produce cavitation, so as to break the solid particles or cell tissue in the liquid. The ultrasonic cell crusher is composed of ultrasonic generator and transducer. The ultrasonic generator circuit converts the 50 / 60Hz commercial power into 18-21khz high-frequency and high-voltage power, The energy is transmitted to the “piezoelectric transducer” and converted into high-fre... -

Bench top cheap price ultrasonic spray coater for fuel cells nano thin film coating

Ultrasonic nozzles operate by converting high frequency sound waves into mechanical energy that is transferred into a liquid, creating standing waves. As the liquid exits the atomizing surface of the nozzle, it is broken into a fine mist of uniform micron sized droplets. Unlike pressure nozzles, ultrasonic nozzles do not force liquids through a small orifice using high pressure in order to produce a spray. Liquid is fed through the center of a nozzle with a relatively large orifice, without p... -

high uniformity ultrasonic thin film spray coating system for fuel cell

Ultrasonic nozzles operate by converting high frequency sound waves into mechanical energy that is transferred into a liquid, creating standing waves. As the liquid exits the atomizing surface of the nozzle, it is broken into a fine mist of uniform micron sized droplets. Unlike pressure nozzles, ultrasonic nozzles do not force liquids through a small orifice using high pressure in order to produce a spray. Liquid is fed through the center of a nozzle with a relatively large orifice, without p... -

ultrasonic biodiesel processor for oil water nanoemulsion mixing

When you make biodiesel, slow reaction kinetics and poor mass transfer are lowering your biodiesel plant capacity and your biodiesel yield and quality. JH ultrasonic reactors improve the transesterification kinetics significantly. Therefore lower excess methanol and less catalyst are required for biodiesel processing. Biodiesel is commonly produced in batch reactors using heat and mechanical mixing as energy input. Ultrasonic cavitational mixing is an effective alternative means to achieve a ... -

ultrasonic biodiesel reactor continuous liquid chemic mixer for nanoemulsion emulsifier

When you make biodiesel, slow reaction kinetics and poor mass transfer are lowering your biodiesel plant capacity and your biodiesel yield and quality. JH ultrasonic reactors improve the transesterification kinetics significantly. Therefore lower excess methanol and less catalyst are required for biodiesel processing. Biodiesel is commonly produced in batch reactors using heat and mechanical mixing as energy input. Ultrasonic cavitational mixing is an effective alternative means to achieve a ... -

mini ultrasonic homogenizer mixer machine for micro cement concrete mixing

Micro silica is widely used in concrete, which makes concrete have higher compressive strength, water resistance and chemical resistance. This can reduce material costs and energy consumption. New nano materials, such as nano silica or nanotubes, lead to further improvement of resistance and strength. Nano silica particles or nanotubes are transformed into nano cement particles in the process of concrete solidification. Smaller particles lead to shorter particle distance, and materials with h... -

1000w lab portable ultrasonic concrete mixer machine for cement nano materials mixing

Micro silica is widely used in concrete, which makes concrete have higher compressive strength, water resistance and chemical resistance. This can reduce material costs and energy consumption. New nano materials, such as nano silica or nanotubes, lead to further improvement of resistance and strength. Nano silica particles or nanotubes are transformed into nano cement particles in the process of concrete solidification. Smaller particles lead to shorter particle distance, and materials with h...