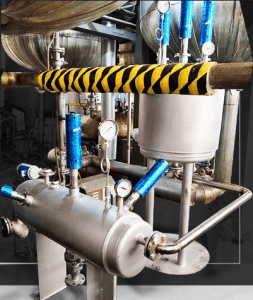

ultrasonic carbon nanotubes dispersion machine

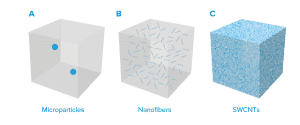

Carbon nanotubes have many uses, and can be used in adhesives, coatings, polymers and as conductive fillers in plastics. By using carbon nanotubes, the polymer’s high temperature resistance, corrosion resistance, pressure resistance and wear resistance have been significantly improved.

Ultrasonic waves generate powerful shearing forces through 20,000 vibrations per second. The bonding force between carbon nanotubes can be overcome, and the tubes are separated evenly. Generally, the crude nanotube dispersion is pre-mixed by mechanical stirring, and then further dispersed into small beams or single carbon nanotubes using ultrasonic waves. It is recommended to use pipeline ultrasonic equipment.

SPECIFICATIONS:

| Model | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | NO | |||

ADVANTAGES:

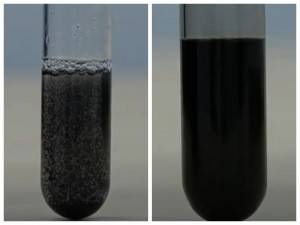

1.Compared with the dispersion in the traditional harsh environment, ultrasonic dispersion can reduce the damage to the structure of single-walled carbon nanotubes and maintain a long single-walled carbon nanotube.

2.It can be completely and evenly dispersed to better achieve the performance of carbon nanotubes.

3.It can quickly disperse carbon nanotubes, avoid degradation of carbon nanotubes, and obtain high concentration carbon nanotube solutions.